I have such Tension headaches! How can I get rid of them for good?

Posted by Ramona McKee on 19th Sep 2022

Every machine has at least two tension settings – upper and bobbin – we are going to address both here.

Bobbin tension – This works for both home flatbed machines and larger multi-needle machines. Your bobbin tension should be checked periodically and anytime you open a new box of pre-wound bobbins or a new cone of bobbin thread. This is because from cone to cone, box to box – the thread can be slightly different. So, let’s get started.

First, you need to run an H test – or L or I – all of these have both horizontal and vertical lines to stitch which will show tension in both directions. If you do not have a test design file a quick google search will help you find one or you can create one using the block letters preloaded on your machine. I also suggest stitching this test using a smaller hoop, a med weight cut away, and a woven quilter’s weight cotton fabric, a woven shirt weight cotton/poly blend can also be used.

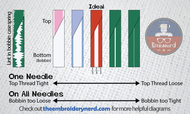

Now that you have run your test look at it... first the front. Is the stitching smooth on all edges, and are the threads spaced and laying nicely? And turn it over – your bobbin thread should run down the center of the two outside layers of the top thread. Think Oreo cookie… you want to crunchy cookies with a creamy white center – equally divided in thirds.

If your bobbin thread is narrower than your top thread – your bobbin tension is too tight. If your bobbin thread is much wider, it is too loose. Now it’s time to adjust your bobbin tension. You’ll need a tiny flat blade screwdriver, there should be one in your machine tools. To tighten the bobbin tension, you turn the screw to the right. To loosen it, you turn to the left. I’m sure we’ve heard it before but it’s true and makes it easy to remember: Righty Tighty, Lefty Loosey.

And how much do you turn the screw? That depends on how much you need to adjust. I work in fractions – I will start by turning the screw ½ turn and run the test again. I keep this fraction until I see a noticeable change when it gets closer, I change to ¼ turn and eventually 1/8 turns until the tension is set where I need it. After every turn, I run the test again – remember you are looking for your Oreo cookie. That cookie doesn’t have to be perfect – it might be a bit zaggy on the edges – that’s ok we just want to get the best we can to equal thirds.

Ok, your home flatbed machines are done. Your machine’s upper tension should be checked and adjusted by your service tech at your annual visits. Now for the upper tension on the multi-needle machines.

Yep you guessed it you need to run another full H test – this time we are looking for something different. With your bobbin tension now set we need to work with the upper tension. And while your test is running let me explain how my process came about.

I attend machine maintenance classes as well as the embroidery and digitizing classes when I go to conferences. One of my favorite instructors is Bill Garvin – you can find You Tube videos of his work. And one of the thing that he said that caught my attention is that all those knobs up top should all be the same – If you look down the profile of you machine and your knobs look like the up and down horses on a carousel they need to be adjusted. And once they are adjusted, they should never have to be changed unless you are running different thread weights. You’ll want to be tighter for lighter weight thread and looser for bulkier decorative threads. But for the most part they should all be the same.

Is your test done? Awesome – now look at the back of the test – remember that Oreo cookie... I bet everyone of your cookies (thread/needle colors) is different. Yep, mine were too. And here is what I used to fix that: Calipers. If you don’t happen to have a pair at home, you can find them at just about any hardware store and unless you plan to use them for other things you don’t need the most expensive set you find either. Mine I found at Harbor Freight for $2 and got them free with a coupon! What is important, and I only mention it because I don’t know if they all do this, is to find a pair that has the depth gauge/rod that pokes out the bottom. Trust me, it will be your best tension-setting friend!

This is mine. When you look at it you can see a bit of an old plastic ruler taped to it – I use it as a flat edge to rest on the top of the knobs –

Ok, back to the test. Look at it, which needle gave you the test Oreo cookie? We are going to use our gauge and set all our knobs to that setting. Pull the depth gauge rod out on your caliper and now adjust it so the flat edge (my plastic ruler bit) sits flat to that knob. Without moving the rod starting at the first knob and determine if it is too high or too low and turn the knob accordingly to get it to match the measurement you took of the first knob. There you go! Now adjust all the knobs to the same measurement. And if your machine has two sets of upper tension knobs, you’ll need to re-measure for the second set and adjust all those knobs using the same setting for that second set.

Now run your test again. It should be all but perfect! And that is a good thing!

Congratulations, you have now beaten the tension monster! Have fun and know you got this!